Actual constructions will manipulate alloys and overall structure to improve capacities, lifespan, and so on, but the chemistry is pretty straightforward: the negative side of the battery will be pure, metallic lead (or whatever alloy is being used - lead-antimony is common), and it will be the oxide equivalent on the positive side, both of which will be submerged in a water/sulfuric acid electrolyte. Because I have a flooded lead acid battery bank and that’s where my experience is, that’s what I’ll be covering.įlooded lead acid batteries are built of a series of lead plates submerged in a sulfuric acid bath (the electrolyte). Others, such as lithium and AGM, are virtually maintenance-free. The most common, flooded lead acid, are the most maintenance-needy with their somewhat regular requirement to be watered.

It’s no exaggeration to say that I’ve read A LOT about the batteries used in RVs. It includes only the tasks that I’ve done for longevity purposes rather than being primarily cosmetic (e.g., polishing the front diamond plate). The following documents the major processes I’ve developed for maintaining ours, a 2017 Timber Ridge 25RDS by Outdoors RV.

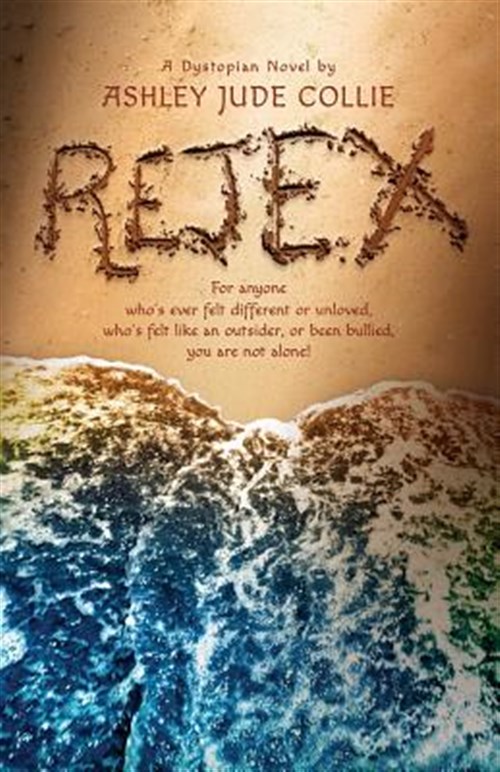

#REJEX LONGEVITY MANUAL#

Unfortunately, the manual isn’t much help in that area - its very vague descriptions of the maintenance tasks needed seem more oriented towards sending you to the dealer than becoming self-sufficient with your RV. Between heat and cold, dry air and humid air, winter road chemicals, sea salt spray, road bounce, and the various other conditions a travel trailer can find itself in, maintenance needs are a certainty.

0 kommentar(er)

0 kommentar(er)